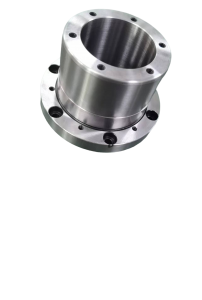

CNCturning Aluminium e entsoeng ka tloaelo, tšepe e sa hloekang, likarolo tse nepahetseng tsa machining Precision machining

Tlhaloso ea Sehlahisoa

Lisebelisoa tsa ho lokisa mochini oa cnc / CNC lathe / mochini o silang / mochini o silang / lathe / ho seha mohala joalo-joalo.

Aluminium alloy ea lintho tse ka tloahelehang:

5052/6061/6063/6065/2017/7075 joalo-joalo.

Alloy ea Brass:

3602/2604/H59/H62 joalo-joalo.

Lisebelisoa tsa tšepe tse se nang tšepe:

303/304/316/412/440C joalo-joalo.

Lisebelisoa tsa tšepe tsa Carbon:

Tšepe ea carbon / die steel, joalo-joalo.

Re sebetsana le mefuta e meng e mengata ea thepa.Haeba o hloka lisebelisoa tse sa thathamisitsoeng ka holimo, ka kopo ikopanye le rona.

Kalafo ea Bokaholimo e Ntšofalitsoe, E hloekisitsoe, e tlositsoe, e entsoe ka Chrome-plated, Zinc-plated, Nickel-plated, Tinted

Inspection Height gauge, tooth gauge, seletsa sa ho metha video, lisebelisoa tsa ho metha tse mahlakore a mararo, jj.

Mefuta ea faele ea AutoCAD (DXF, DWG), PDF, TIF, IGS, UG, SolidWorks, joalo-joalo.

A na u ka fana ka liphekolo tse holimo bakeng sa likarolo tse entsoeng ka nepo?

Re fana ka mefuta e mengata ea phekolo ea holim'a metsi bakeng sa likarolo tse nepahetseng tse phahameng.Tse ling tsa lintho tsena tse qetellang li kenyelletsa sandblasting, brushing, electroplating le electroplating, passivation, anodizing, chrome plating, polishing, le tse ling.Lisebelisoa tsena li sireletsa likarolo tsa eona maemong a thata, li ntlafatsa ts'ebetso ea karolo kapa li ntlafatsa ponahalo ea eona e ntle.

Ke tseba joang hore meralo ea ka e tla bolokoa e le lekunutu?(Tumellano ea Lekunutu)

Ka botumo ba ho sebetsa le makholo a likete a meralo e ikhethang ho theosa le lilemo, re lula re boloka litaba tsa bareki e le lekunutu 'me re na le maano a thata a behiloeng ka har'a lifeme tsa rona.Haeba ho hlokahala, re ka saena li-NDA le bareki ba hlokang tokomane ena

Nka fumana quote ea tlhahiso joang?

1. Kenya faele ea hau ea CAD

Mohato oa pele ke ho tlatsa lintlha tsa hau le ho kenya faele ea hau ea CAD.Sena se re thusa ho theha mofuta oa 3D oa karolo eo re e batlang kapa prototype.

2. Tlhaloso le tlhahlobo ea moralo

Ka mor'a lihora tse 12, re tla u fa quote le maikutlo a DFM.Sena se tiisa hore morero oa hau o ka etsoa le ho u fa khakanyo e nepahetseng ea litšenyehelo.

3. Laela 'me u qale tlhahiso

Ha u se u amohetse qotsulo le moralo oa hau, re tla qala tlhahiso ea prototype ea hau ea CNC kapa sehlahisoa sa karolo ea mochini oa CNC.

4. Romela 'me u fumane likarolo tsa hau

Likarolo kapa lihlahisoa tse entsoeng ka mochini oa CNC li tla hlahisoa ka mor'a matsatsi.Re romella ho uena ka Express Express.Ka kopo ikutloe u lokolohile ho re fa maikutlo ho etsa bonnete ba hore li fihlella litebello tsa hau.

Ho etsa machining a boleng bo holimo ho hloka bokhoni bo bongata ba ho qaqisa le ho latela moralo o ikhethileng ho etsa lihlahisoa tse makatsang.Ha u batla liphetho tse ntle, ho sebetsa le k'hamphani e tšepahalang ea machining ho bohlokoa.Re fana ka mefuta e mengata e fapaneng ea lits'ebeletso tsa machining tse nepahetseng ho kenyelletsa ho fetola ka nepo, ho sila, le EDM ho fihlela litlhoko tsa hau tsa boleng.

Ho tloha ho prototype ho isa tlhahiso, ho tloha sekotong se le seng ho isa ho likotoana tse 10,000, re fana ka machining a CNC a fetohang ka potlako bakeng sa likarolo tsa hau tsa tšepe le polasetiki, ka ho tsamaisoa ka potlako joalo ka matsatsi a 3.

Re ka hlahisa likarolo tse rarahaneng tse phahameng tse nang le mamello e lekaneng ea ± 0.01 mm, mamello ea geometrical ea 0.01 mm, radius e nyenyane ea machining ea R0.1mm, le machining surface roughness ea Ra0.2μm.Hape hangata re phephetsa likarolo tsa optical tse nang le lintlha tse nepahetseng.

Ke mofuta ofe oa ho qetela oo machining oa CNC a o sieang morao?

Kamora hore ts'ebetso ea machining e phetheloe, bokaholimo ba karolo ea CNC bo tla ba le matšoao a sesebelisoa a bonahalang hanyane, a bitsoang "machine" kapa "machine" a holimo.Mathata a holim'a mochini (Ra) a tloaelehile ho 1.6-3.2 μm, 'me litlhoko tsa ho qeta holimo li ka phahamisetsoa ho 0.8-1.6 μm kapa holimo ho 0.2-0.8 μm, empa sena se tla hloka nako e eketsehileng ea ho sebetsa le litšenyehelo tse phahameng.

Nako ea hau ea ho fana ke mang?

Ha e le hantle, ha ho na nako e tloaelehileng ea ho fana ka nako, re tla hlophisa tlhahiso ho latela mosebetsi oa hona joale.Hang ha odara ea hau ea theko e se e amohetsoe, litokomane li felile, 'me lisebelisoa li se li lokile, re tla fana ka maikutlo a potlakileng mabapi le nako e nepahetseng ea ho fana, eo hangata e tlohang matsatsing a 3 a khoebo ho isa libekeng tse' maloa, ho latela ho rarahana ha karolo le bongata ba likarolo tse laetsoeng. .