OEM customized CNC likarolo, ho fetola likarolo

Tlhaloso ea Sehlahisoa

Lisebelisoa tsa ho lokisa mochini oa cnc / CNC lathe / mochini o silang / mochini o silang / lathe / ho seha mohala joalo-joalo.

Aluminium alloy ea lintho tse ka tloahelehang:

5052/6061/6063/6065/2017/7075 joalo-joalo.

Alloy ea Brass:

3602/2604/H59/H62 joalo-joalo.

Lisebelisoa tsa tšepe tse se nang tšepe:

303/304/316/412/440C joalo-joalo.

Lisebelisoa tsa tšepe tsa Carbon:

Tšepe ea carbon / die steel, joalo-joalo.

Aluminium alloy ea lintho tse ka tloahelehang:

5052/6061/6063/6065/2017/7075 joalo-joalo.

Alloy ea Brass:

3602/2604/H59/H62 joalo-joalo.

Lisebelisoa tsa tšepe tse se nang tšepe:

303/304/316/412/440C joalo-joalo.

Lisebelisoa tsa tšepe tsa Carbon:

Tšepe ea carbon / die steel, joalo-joalo.

Re sebetsana le mefuta e meng e mengata ea thepa.Haeba o hloka lisebelisoa tse sa thathamisitsoeng ka holimo, ka kopo ikopanye le rona.

Kalafo ea Bokaholimo e Ntšofalitsoe, E hloekisitsoe, e tlositsoe, e entsoe ka Chrome-plated, Zinc-plated, Nickel-plated, Tinted

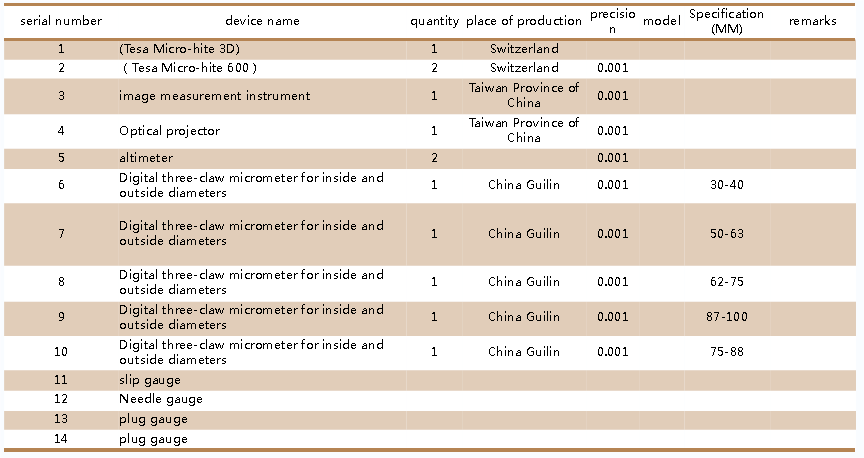

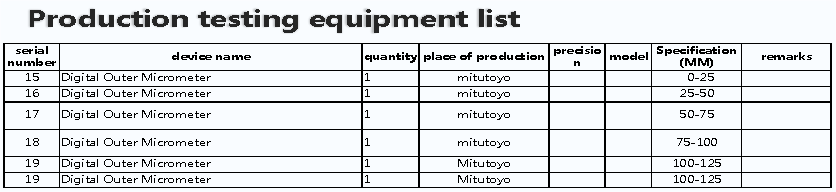

Inspection Height gauge, tooth gauge, seletsa sa ho metha video, lisebelisoa tsa ho metha tse mahlakore a mararo, jj.

Mefuta ea faele ea AutoCAD (DXF, DWG), PDF, TIF, IGS, UG, Solidworks, joalo-joalo.

Lethathamo la lisebelisoa tsa tlhahlobo ea tlhahiso

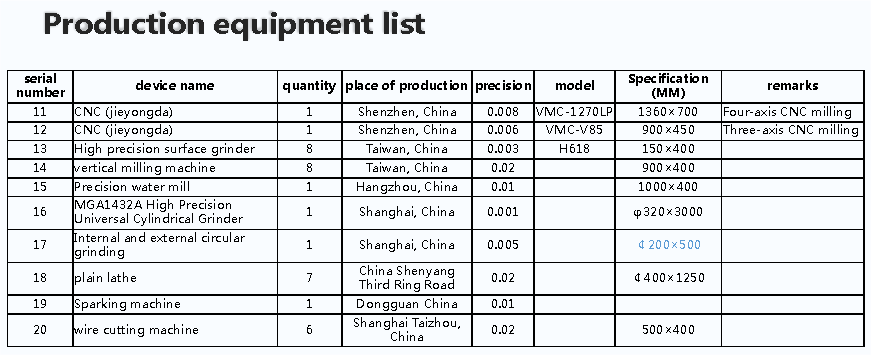

1.CNC likarolo tsa machining:

CNC turning ke mokhoa o itirisang oa mosebetsi o eketsang haholo ts'ebetso ea ho fetola CNC hangata e na le sekhahla se tlase sa liphoso le karolo ea boleng bo holimo ho feta phetolo ea matsoho ts'ebetsong e ikemetseng.

Ho fetoha ha CNC ho loketse ka ho phethahetseng bakeng sa tlhahiso ea likarolo tse nyane le tse mahareng.

CNC turning ke mokhoa o ikemetseng oa mosebetsi o ntlafatsang haholo ts'ebetso le ho boloka litšenyehelo tsa basebetsi, ho fella ka phokotso e akaretsang ea karolo ea litšenyehelo.

2. Ho sebetsa ka mokhoa o nepahetseng oa CNC:

U hloka ho fumana mamello e tiileng ea ± 0.005mm kapa ho feta.

Ka boiphihlelo bo netefalitsoeng, theknoloji e tsoetseng pele ea CNC le lisebelisoa tsa tlhahlobo, re na le boiphihlelo ba ho fana ka ho nepahala le ho pheta-pheta, esita le bakeng sa likarolo tse rarahaneng ka ho fetisisa.Re ikemiselitse ho fana ka lits'ebeletso tse nepahetseng tsa mochini oa CNC tse fihlelang kapa tse fetang litebello tsa bareki ba rona.

Lipalangoang tsa sefofane

Ho tsamaisa ka sekepe

Se Kenyellelitsoeng Khopolong ea Marang-rang

1. Kenya faele ea hau ea CAD

Mohato oa pele ke ho tlatsa lintlha tsa hau le ho kenya faele ea hau ea CAD.Sena se re thusa ho theha mofuta oa 3D oa karolo eo re e batlang kapa prototype.

2. Tlhaloso le tlhahlobo ea moralo

Nakong ea lihora tse 12, re tla u fa khotheishene le maikutlo a DFM.Sena se tiisa hore morero oa hau o ka etsoa le ho u fa khakanyo e nepahetseng ea litšenyehelo.

3. Laela 'me u qale tlhahiso

Ha u se u amohetse qotsulo le moralo oa hau, re tla qala tlhahiso ea prototype ea hau ea CNC kapa sehlahisoa sa karolo ea mochini oa CNC.

4. Romela 'me u fumane likarolo tsa hau

Likarolo kapa lihlahisoa tse entsoeng ka mochini oa CNC li tla hlahisoa ka mor'a matsatsi.Re romella ho uena ka Express Express.Ka kopo ikutloe u lokolohile ho re fa maikutlo ho etsa bonnete ba hore li fihlella litebello tsa hau.

Ho etsa machining a boleng bo holimo ho hloka bokhoni bo eketsehileng le ho khomarela ka botlalo lipolane tse khethehileng ho etsa lihlahisoa tse makatsang.Ha u batla liphetho tse ntle, ho sebetsa le k'hamphani e tšepahalang ea machining ho bohlokoa.Re fana ka mefuta e mengata e fapaneng ea lits'ebeletso tsa machining tse nepahetseng ho kenyelletsa ho fetola ka nepo, ho sila le EDM ho fihlela litlhoko tsa hau tsa boleng.

Nako ea hau ea ho fana ke mang?

Ha e le hantle, ha ho na nako e tloaelehileng ea ho fana ka nako.Re tla hlophisa tlhahiso ho latela mosebetsi oa hona joale.Hang ha odara ea hau ea theko e se e amohetsoe, litokomane li felile, 'me lisebelisoa li se li lokile, re tla fana ka maikutlo a potlakileng mabapi le nako e nepahetseng ea ho fana, eo hangata e tlohang matsatsing a 3 a khoebo ho isa libekeng tse' maloa, ho latela ho rarahana ha karolo le bongata ba likarolo tse laetsoeng. .

FQA

Litheko tsa rona li ka fetoha ho latela phepelo le lintlha tse ling tsa 'maraka.Re tla u romella lenane le ntlafalitsoeng la litheko kamora hore k'hamphani ea hau e iteanye le rona bakeng sa tlhaiso-leseling e batsi.

Ee, re hloka hore liodara tsohle tsa machabeng li be le palo e tsoelang pele ea odara.Haeba u batla ho rekisa hape empa ka bongata bo fokolang haholo, re khothaletsa hore u hlahlobe sebaka sa rona sa Marang-rang.